- BACK

- Clutch Release Mechanism and Bell Housing

- Much has been written about this assembly and the failings due to poor design

- and itting and servicing. I refer once again to a proper pioneer Malcolm Robb who

- has already experienced first hand many years ago most, if not all of the possible

- problems. www.lotus-carlton.fsnet.co.uk

- I had the opportunity of helping a fellow club member to change the bell housing,

- pivot pin and clutch friction disc. The symptoms were as usual a very stiff creaky

- clutch. History was that the bell housing , friction disc, pivot pin and retaining

- screw had been replaced December 2002. In Dec 2003 the pin and retaining

- screw were replaced again. Surprisingly the work was carried out by Monorep,

- who I had always held in high regard.........I suppose it's down to the individual

- fitter on the day, not helped by poor design, however this should have been fitted

- properly first time around, I'm not convinced that the pin was actually replaced

- Dec 2003 at all, and certainly not lubricated in any way.

- First jobs were to remove the gear lever assembly from the gearbox from within

- the car. This requires removal of the gear lever surround and rubber gaiter beneath

- to gain access to the 4 bolts that secure the lever assembly to the gearbox.

- Noted as is also most common was that the rubber gaiter was split and chewed

- up, my bet is that the dealers cut holes in the gaiter to get to the bolts, instead of

- drilling out the rivets which secure the gaiter retaining plate to the transmission

- tunnel.

- This was mine. It is not a good idea to try and fit a new gaitor after the gearbox and exhaust is

- back in place especially if you are trying to use nuts and bolts to re-secure the metal frame which

- holds it all in place ;-) To do a proper job you would probably need to lift the centre console up and

- put new pop-rivets in. I wanted to be able to easily remove the gaitor for the next time the gearbox

- needs to come out.

- With the gear lever assembly removed, the rest of work is done from underneath

- the car. Next disconnect and remove the offside down pipe with cat, a nice surprise

- was that the other down pipe can be left in position, this would have been a pain to

- remove as the connection to the turbo manifold is not easy to see, let alone get to

- the nuts. We would have had to lift the charge cooler to one side but in the event

- was saved this work.

- Remove the nuts holding the large heat shield, slide it back towards the centre

- exhaust boxes, (it would probably be a little easier to remove the rubber hangers

- from the mid boxes first) this will then allow access to the socket head screws

- of the prop shaft to gearbox output flange.

- Whilst supporting the gearbox, remove the cross member and mount, I also

- removed the mount bracket.Lower the gearbox down until the back of the

- cylinder head rests against the front bulk head. Also whilst lowering the gearbox

- down, keep an eye in the cooling fan as it will foul the cowling and you will

- need to turn it to avoid this.

- At this point it is a good idea to jack up and support the engine from the sump,

- the reason is that when the gearbox is removed the engine will want to tip back

- to its normal position and you need to prevent this. The gearbox is bolted to the

- bell housing and the bell housing bolted to the engine block. The gear box

- comes out first, then remove the screw which secures the clutch release arm

- pivot pin, in this instance it was already loose! The bell housing can then be

- removed After removing the pin and release arm, it became immediately obvious

- why the clutch felt so bad. This shows the release arm view of the socket and

- the pin, bone dry, rusty and pitted.

More of the old pin.

Old and new non vauxhall re-designed pin with hard chromed working surface.

- This shows the damage done to the hole which the pivot pin fits into, the bell housing

- was only 2 years old. Because the pin became loose it rocked backwards and forwards,

- deforming the hole. The owner had already taken the precaution of having his spare bell

- housing modified with a reinforcing plate and modified pin, we decided to fit it. The early

- pin and bell housing versions used a roll pin to prevent the pin from turning even if the

- screw comes loose. Now there is a locating flat on the pin and bell housing.

- In the pic below, it looks as if this has been crushed. (1430-1600hrs), probably accounts

- for the retaining screw being only finger tight, and the deformation of the hole.

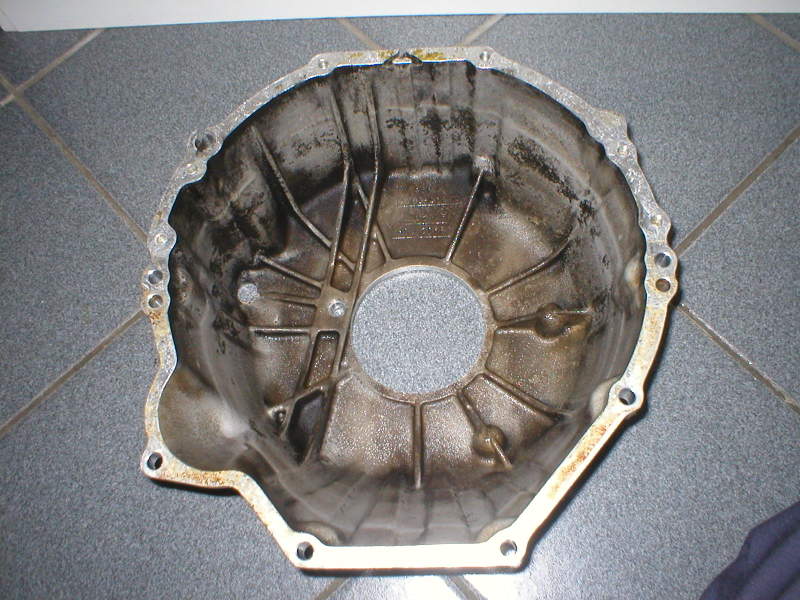

Following pictures show the modification to a previously cracked bell housing.

- Evidence of the original crack still visible, with the modification and stronger pin mount

- plate the stresses are more evenly distributed into the surrounding area.

- The loading stress when the clutch is applied is vertically downwards in the picture,

- pulling the pin through the casting.

- Now fully inspired to check out my own clutch, I have a plan to find some way of

- lubricating the pivot pin without the need for bell housing removal. Another possibility

- would be to somehow encapsulate the fork hole and pin and fill the void with grease

- so that grease cannot escape, or dust get in.

Overview pictures of complete (thanks Ian M)

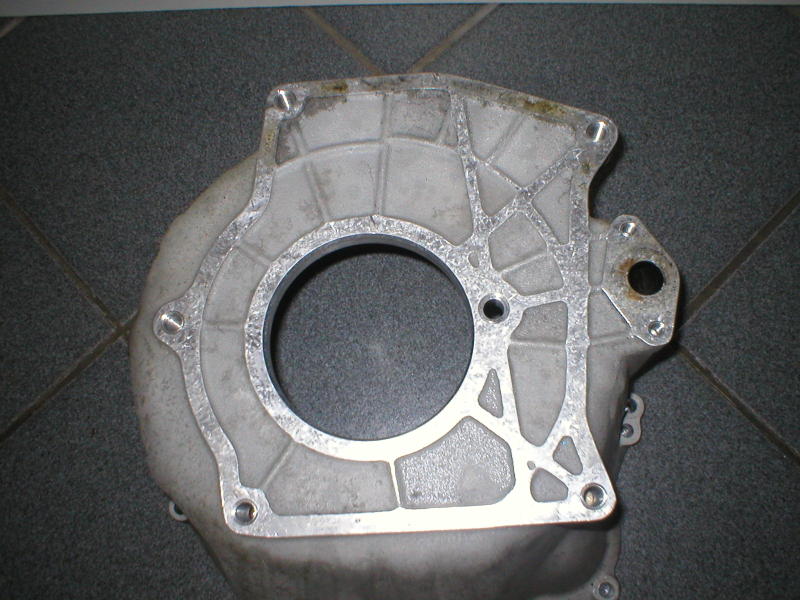

- Below is a picture of an early design bell housing mmm....somthing missing.....

- Compared to above which has more ribs.