|

Links

Gallery

Fixes

Parts

LC tech

For Sale

Z20LET

VXR8

| |

- BACK

-

- Oil Pressure Relief Valve Service

-

- With time and miles the pressure relief valve can

become a bit worn and scored.

- It can collect various debri from the engine which

could make it "sticky" in operation.

- Having seen valves which were not operating as smoothy

as I would expect (that is not to say

- they were'nt controlling pressure as the should) as a

precaution I removed mine for a clean up.

-

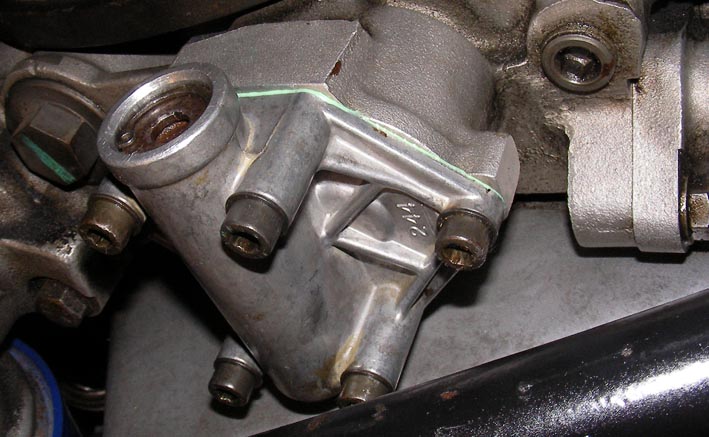

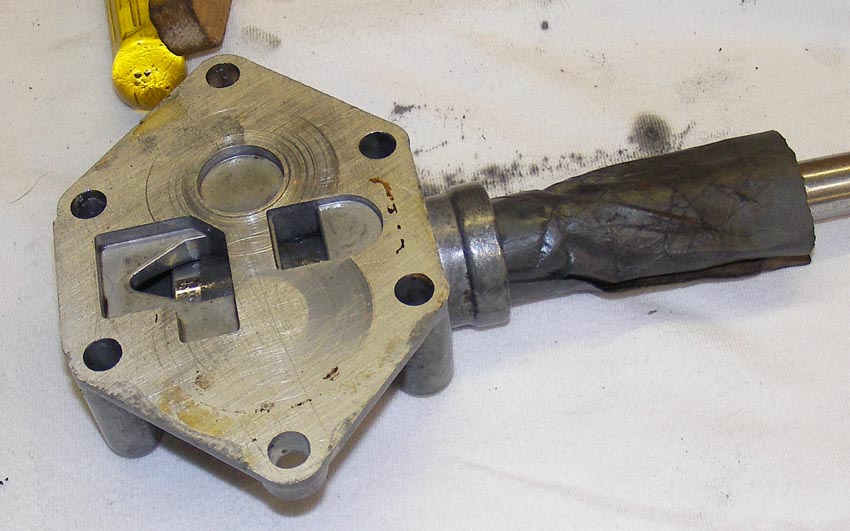

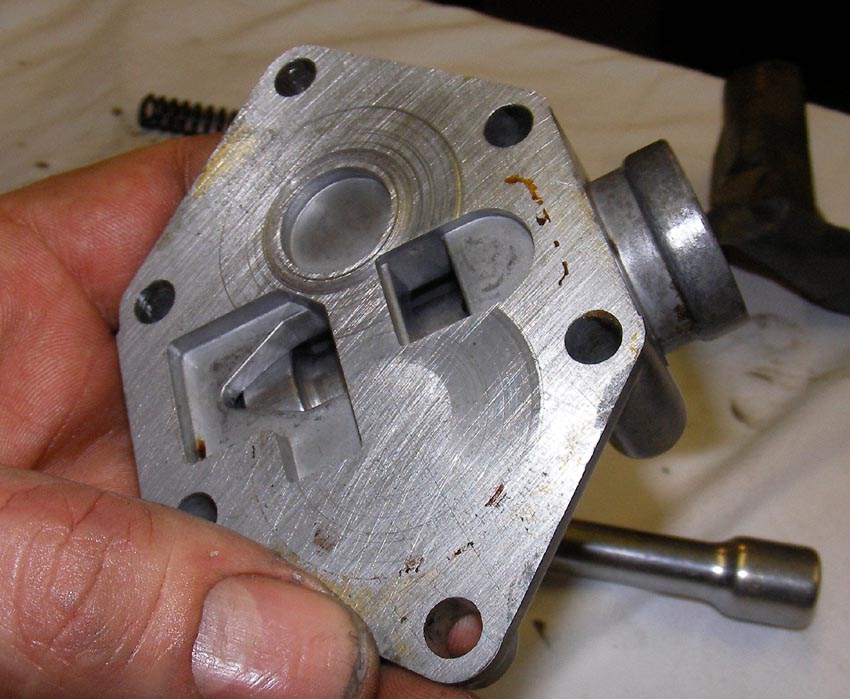

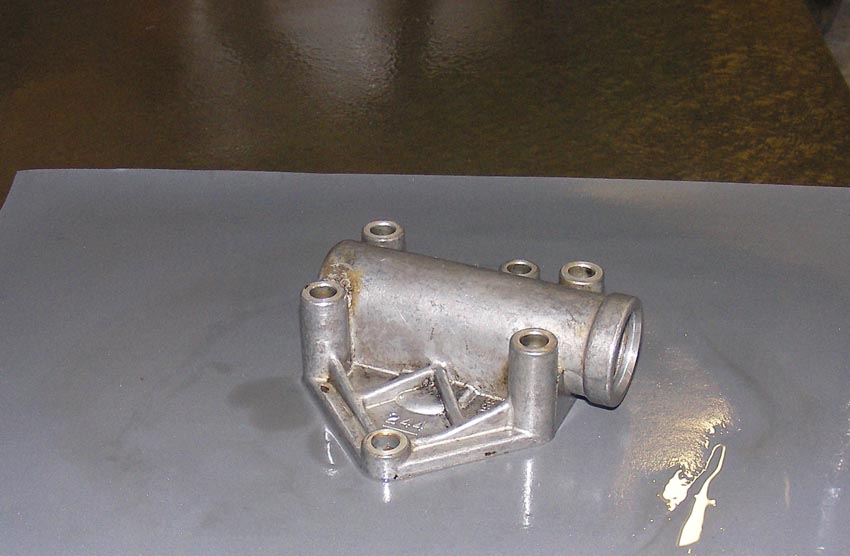

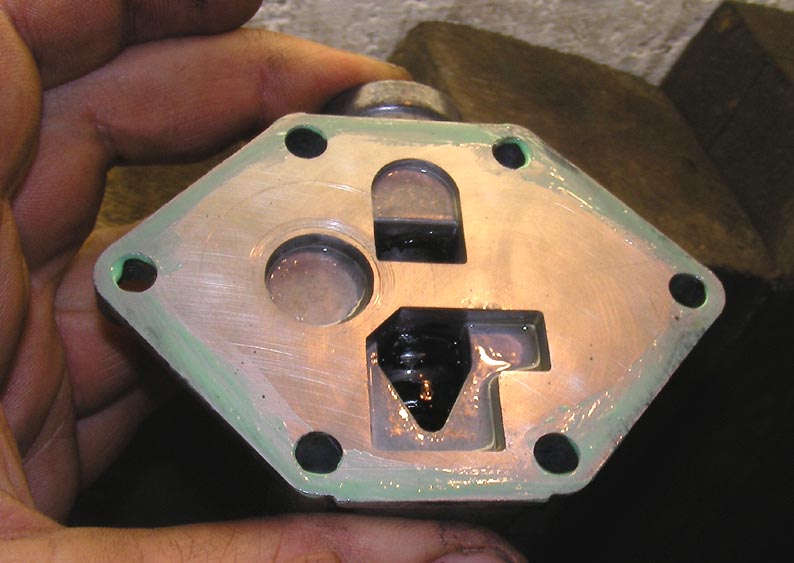

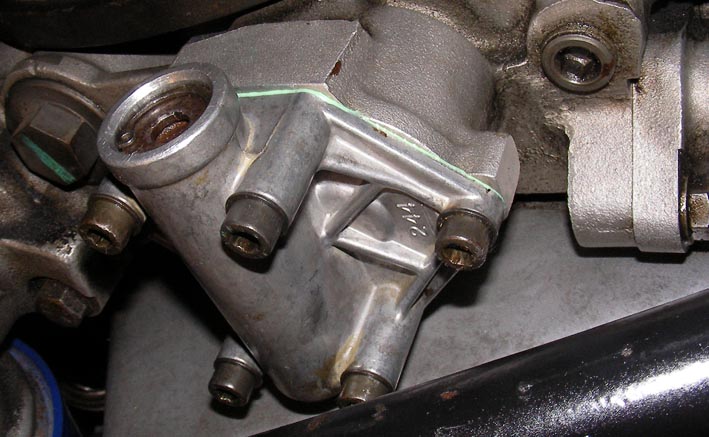

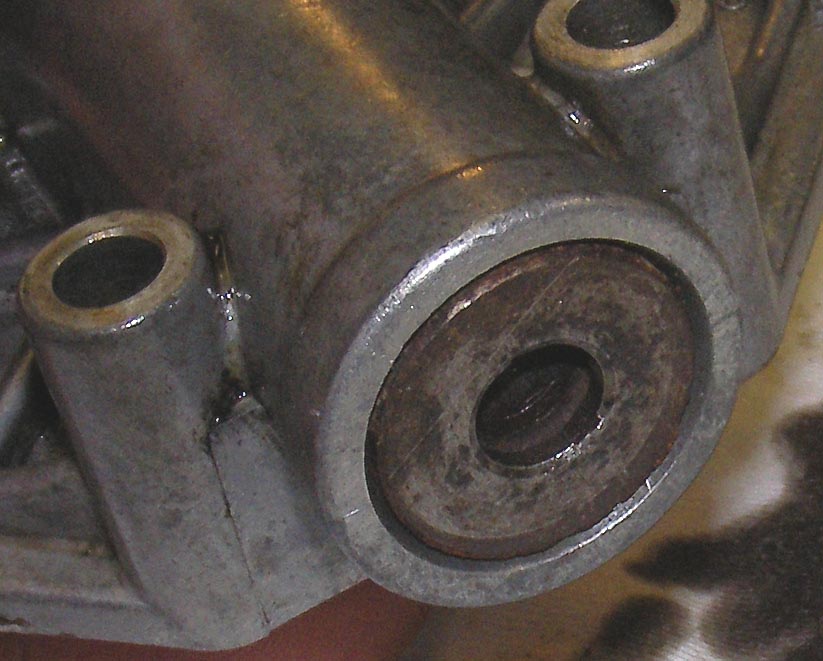

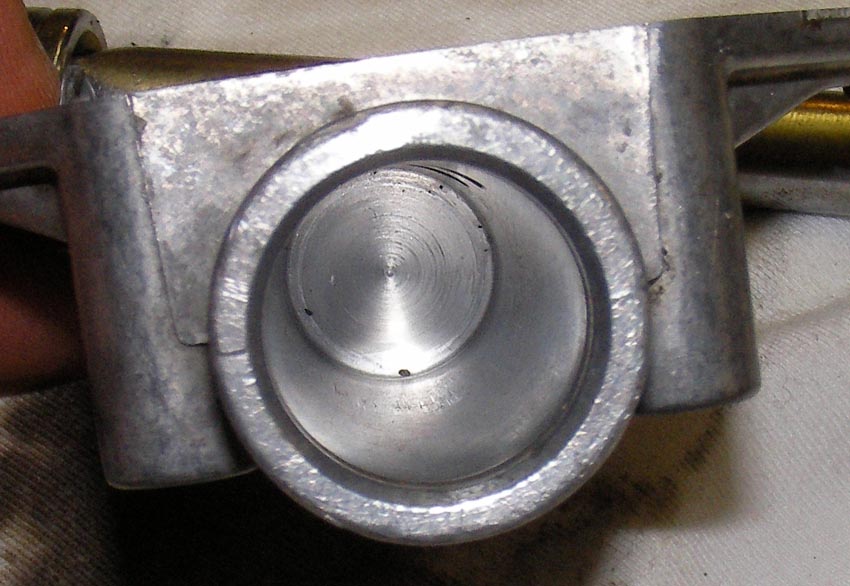

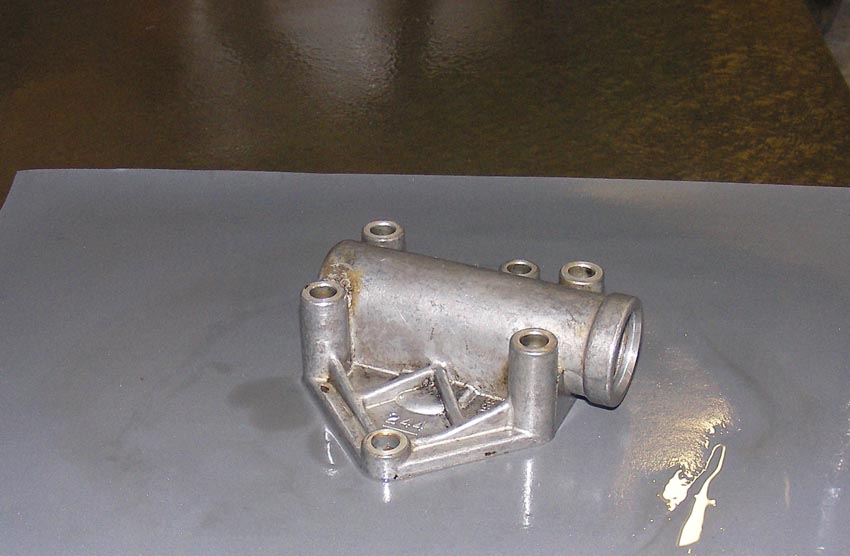

- The valve assembly is located at the bottom of the

front timing cover. The valve can actually be removed

- without taking the complete assembly off. I prefer to

remove the whole assembly so that it can be cleaned

- properly and any burrs or scoring treated

appropriately.

-

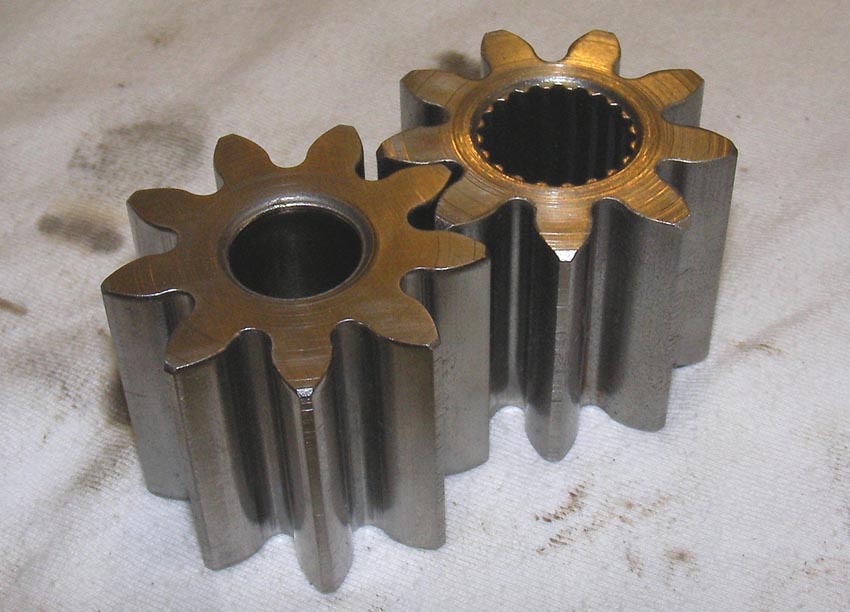

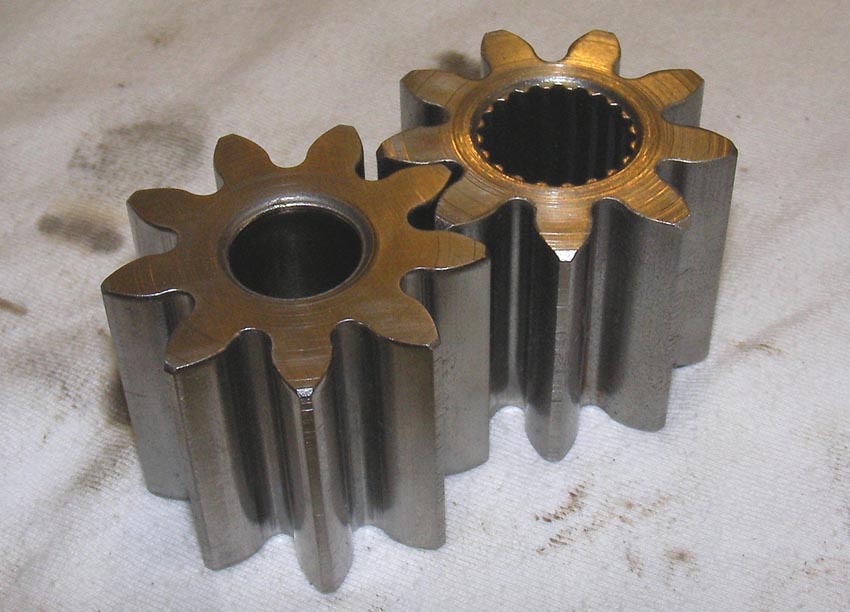

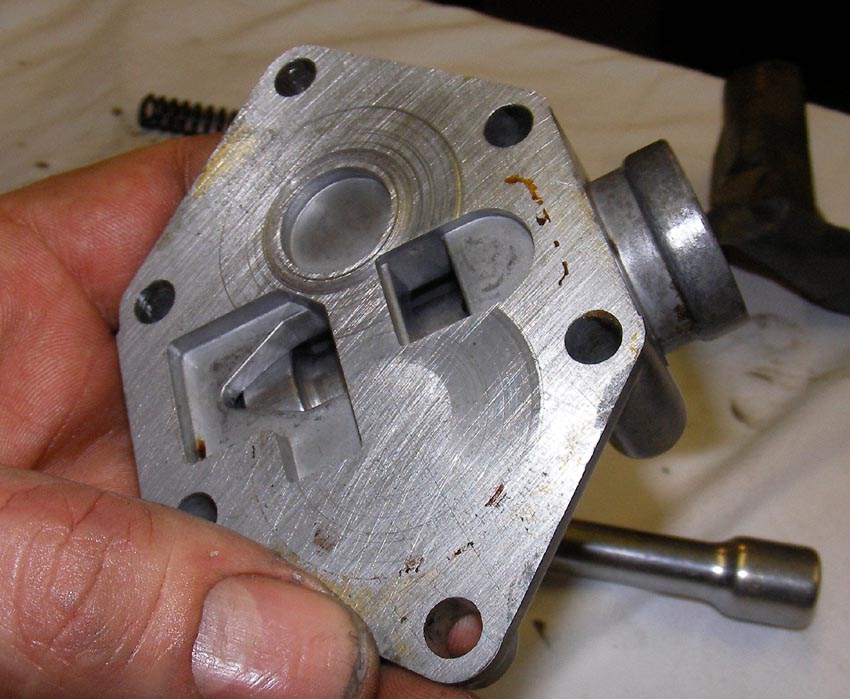

- Remove the six cap head screws and lower the cover

carefully because the pump gears will probably fall

- out at the same time. Be sure to note which way up the

gears are fitted so that they go back the same way.

-

- There is a wear limit for the mesh between cogs, I've

yet to come accross any that were outside the limits,

- in any case new gears are no longer available and not

wanting something else to worry about, these are

- going back in again. :-)

-

- The threads are standard M6 form, and cleaned up

easily, they were a little gummed up with sealer.

-

-

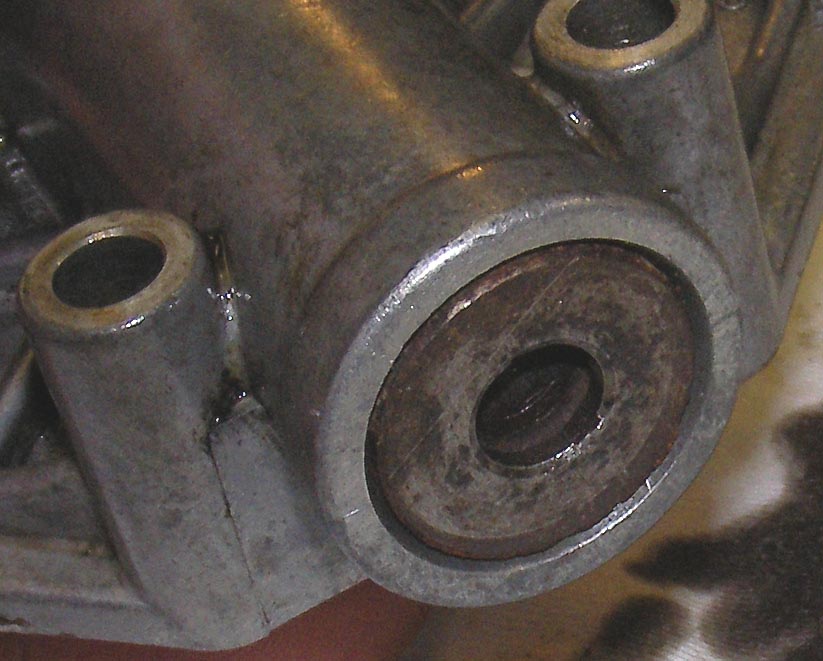

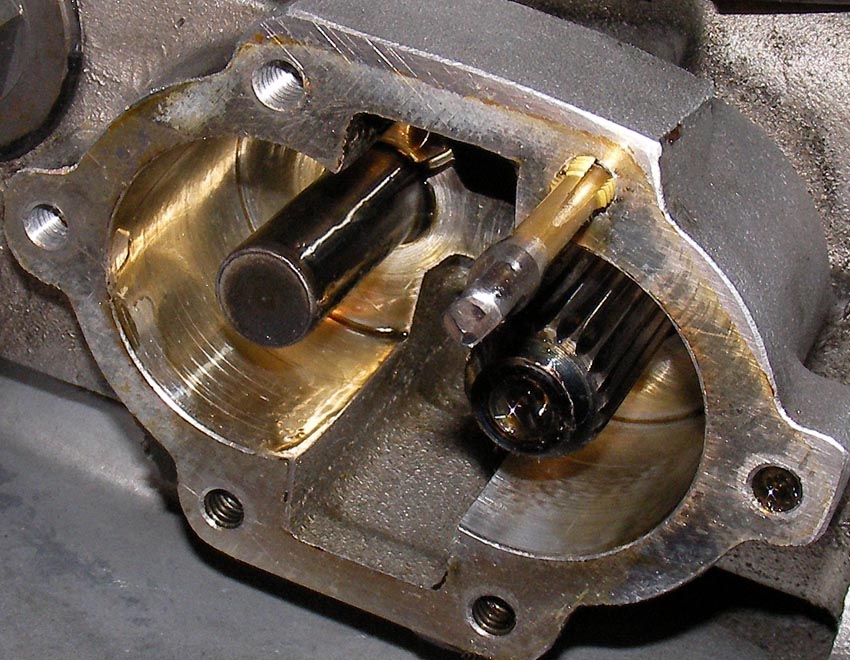

- Remove the circlip.

-

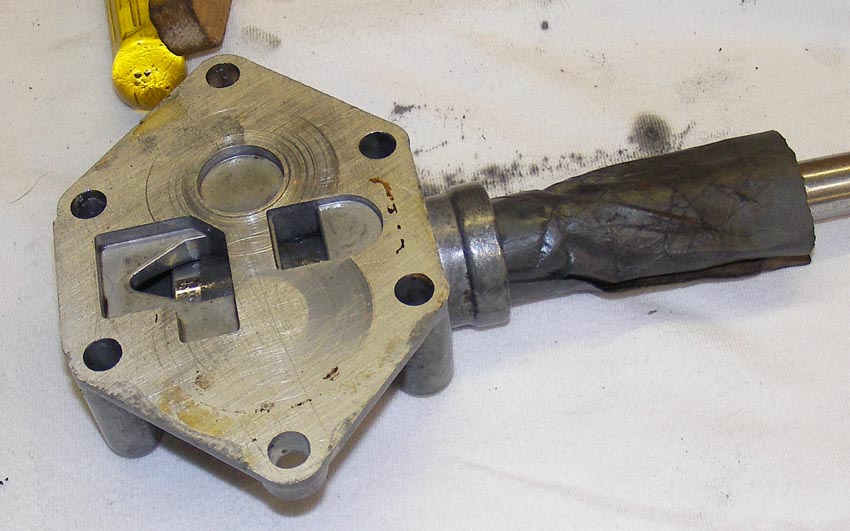

- The valve will not fall out, it will need a little bit

of educating, tapping the end on the bench will bring the

- retaining cap forward enough to remove it. The

retaining cap has an o ring fitted to it.

-

-

-

-

-

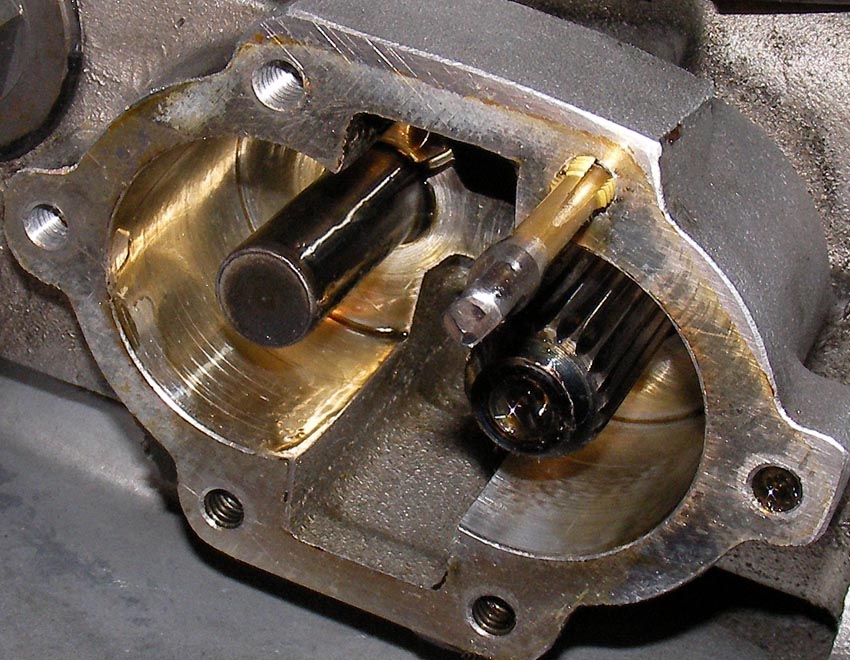

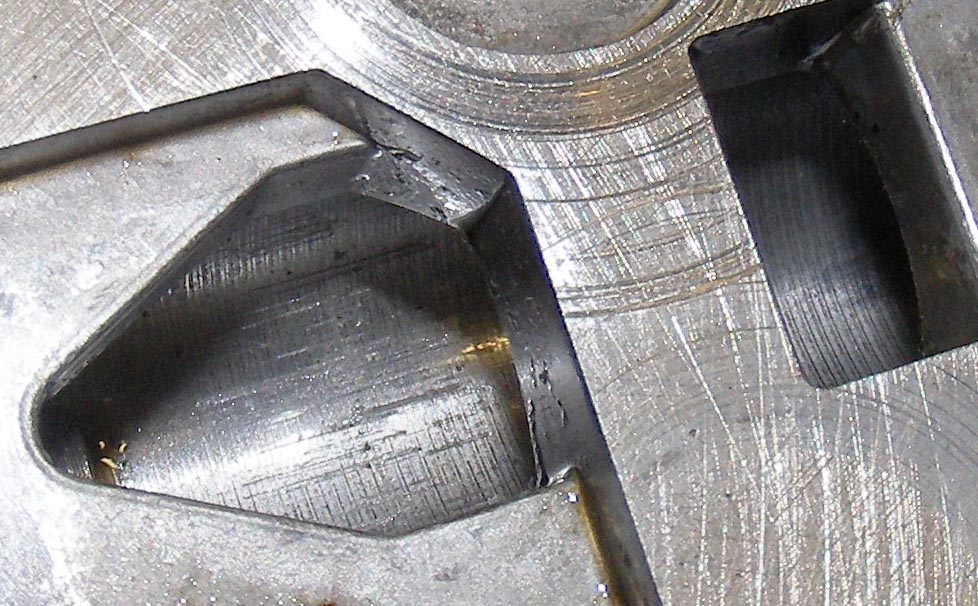

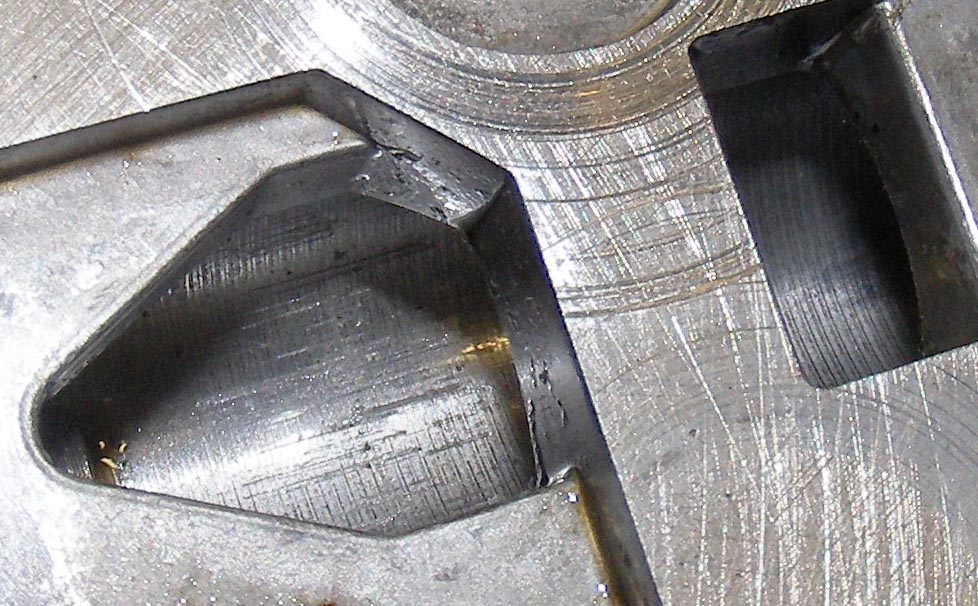

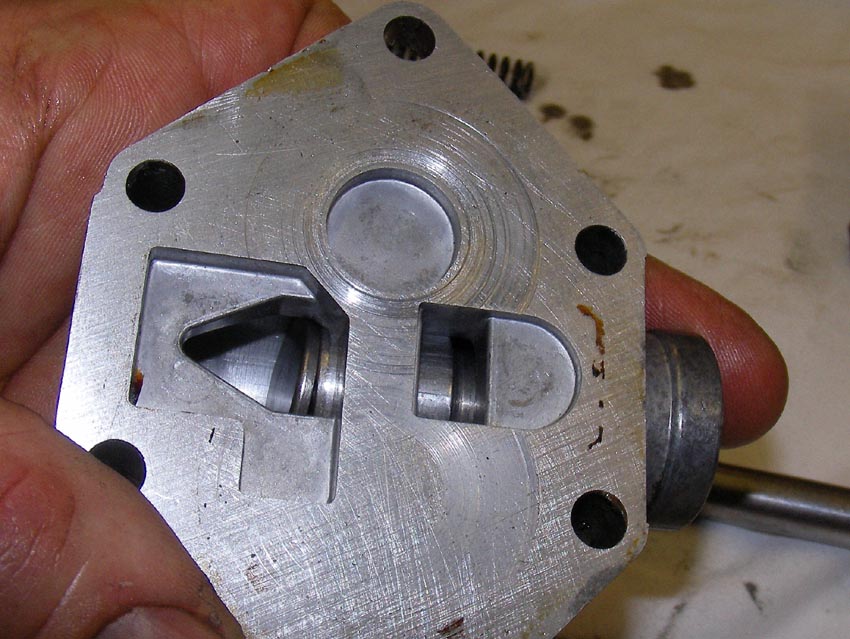

- The valve spindle was not badly scored although when

checking the movement in the housing it was not

- at all smooth.

-

-

- It does not appear to be a precision ground component,

after some work with 1500 grit (used) wet and dry

- paper......just the burrs and roughness were removed.

-

-

-

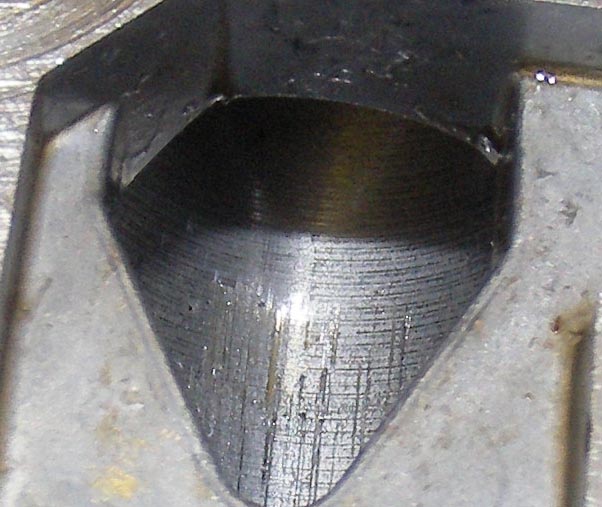

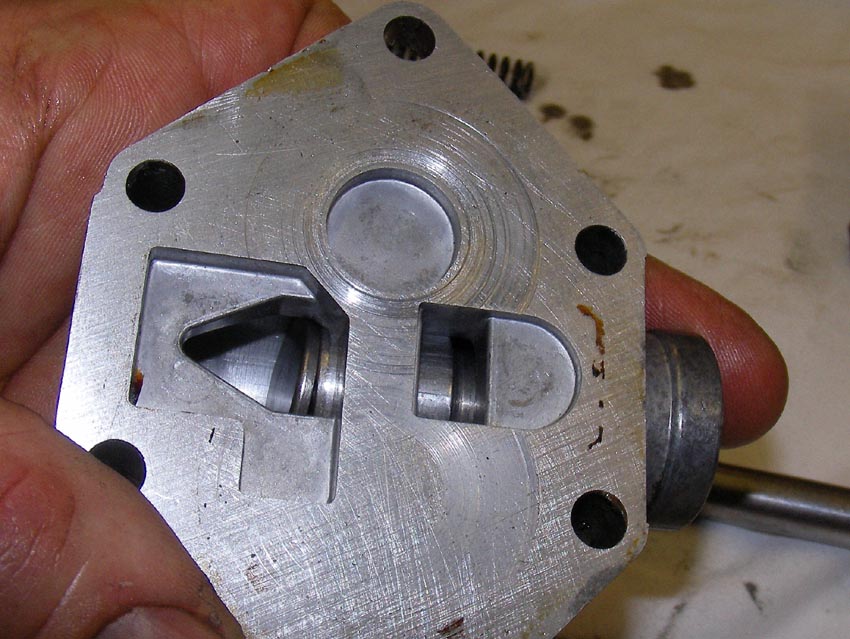

- Next was a look at the bore of the housing.

- Again the machining is not really precision stuff,

using same (used) wet and dry paper wrapped around a

- long series 13mm socket, I carefully slid this inside

the bore and rotated and slid up and down until some

- but not all the scoring was smoother. (liberal amounts

of wd40 helps too). The objective it NOT to remove surface

- material, just to reduce the scoring and remove any

high spots !

-

- Fit was checked and now the valve slides nicely within

the bore.

-

-

-

-

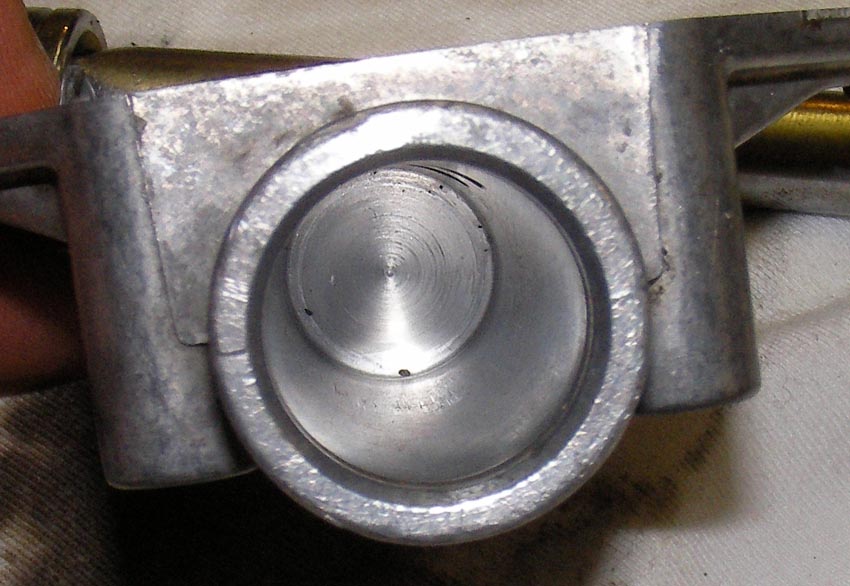

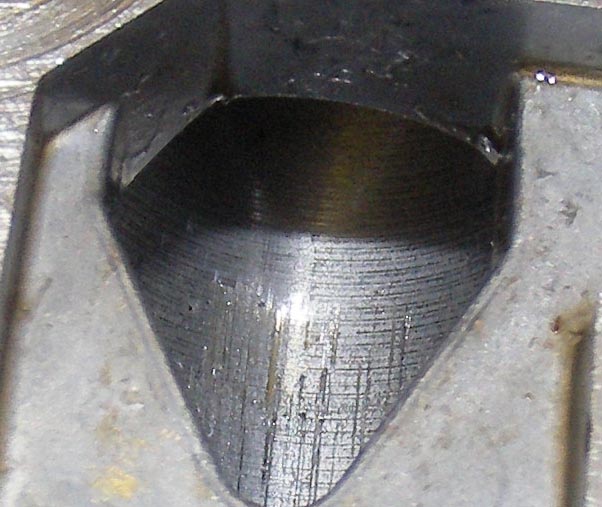

- Next was to lap the mating surface using a new

sheet of 1500 grit wet and dry paper on a surface plate.

- It does not take long at all, perhaps only 20 secs or

so circular motion. Lots of wd40 !

-

- The surface was restored easily, in fact it might even

be a bit too smooth....time will tell.

-

-

-

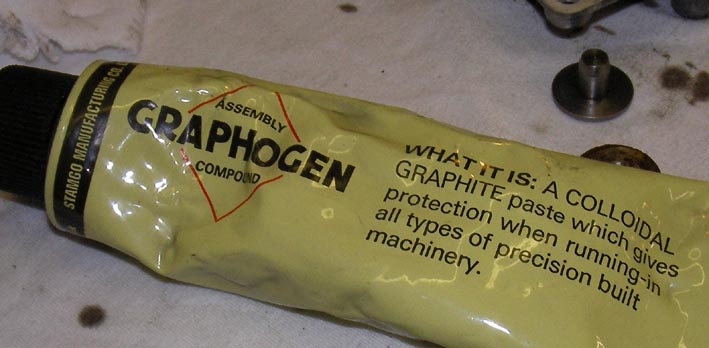

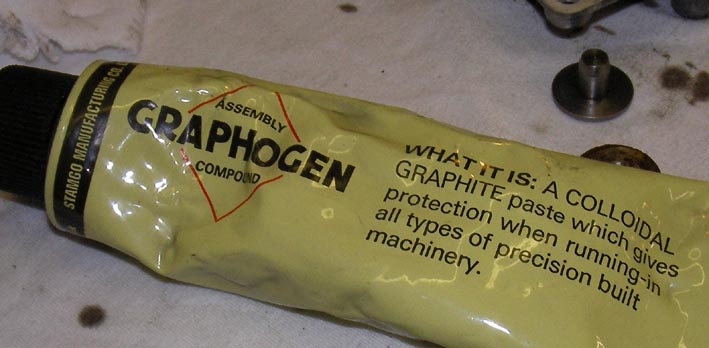

- Re-assemble the valve, can be a little tricky to get

the retaining cap pressed whilst replacing the circlip, I used

- a large g clamp to help this. Graphogen is my favourite

for this, very thick and provides good protection whilst

- initial oil pressure is built up.

-

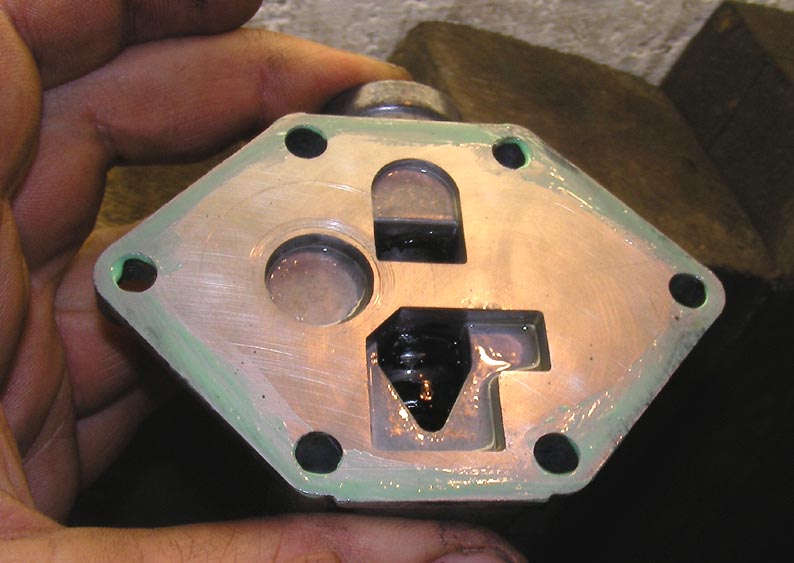

- Special sealer for the pump cover mating face.

-

- Aswell as graphogen paste. I topped up the valve cavity

with oil.

-

- Graphogen was smeared on the pump gears, because the

paste is really thick and sticky, the gears stayed

- in place whilst the cover was put back on.

-

- Once all bolted back on, remove the oil pressure sensor

and with a long spout fill squirt oil into the hole until

- it starts to pour out again, thus priming the oil pump.

Refit the sensor.

-

- Crank engine without the fuel pump running to build the

oil pressure up before starting properly (watch for oil

- light extinguishing on dash) job done.

- Difference ?.....absolutely none, but then I never

expected any difference to be honest, however I can be more

- confident that the relief valve won't give me any

trouble in future.

-

- Update Aug 2009 - I have noticed that when cold

starting the tappets settle down much faster than before,

- so this job was worth the effort imho.

- BACK

-

-

-

-

-

|