- Sump pressure

- There is a thought that vacuum aids drainage of oil from the turbo's, this in turn is supposed

- help to prevent turbo seal leakage. Oil can leak at hot idle when the turbo rotors are not

- spinning very fast. This appears to be a problem in some Lotus Carlton's,

- I've not seen this with mine so far, but want to be at least aware of what's going on.

- Whilst driving, the turbo's spin much faster than at idle and seal leakage does not become a problem.

- (At some point I also want to check the oil pressure to the turbo's at hot idle at a later date.)

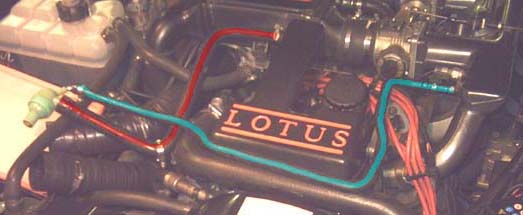

- There is a tube which runs from the inlet manifold to the air box.

- Just after the joint to the manifold is a one way valve which will

- allow air to be drawn into the manifold but will not allow boost leakage.

- The valve has an ident "VAC" on one side, this side should face the manifold.

- The air box lid has been removed and the small green filter assembly put into

- place as if it were inside the air filter box. The blue coloured pipe would normally

- sit under the radiator top hose.

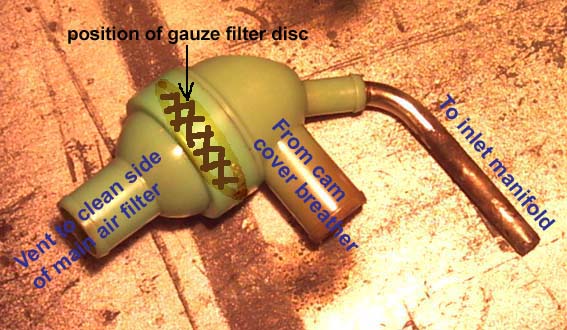

- The cam cover breather hose also connects to the small green filter device.

- The small green filter device has 3 connections, 2 large and one small. The small

- connection has a right angled metal pipe which then pokes through a tube in the

- air box lid, the tube from the inlet manifold then connects to it. One of the other bigger connections

- joins the breather from the cam cover, there is a aluminium restrictor at this joint I'm not sure what

- effect this has at the moment. The third connection vents into the airbox.

- This shows the position of the filter inside the airbox lid.

- There does not seem to be any type of valve device within the green filter unit.

- I can't see how it would be possible to much if any vacuum within the sump as air

- can easily be drawn into the cam cover via the breather hose.

- I measured the hot idle vacuum level in the sump of my senator, I was suprised to find only

- about 0.16psi

- I used a magnehelic differential pressure gauge to measure the sump pressures on the LC. I connected a tube to the dipstick hole and the other end to the gauge. The gauge I used measures negative or positive pressure up to 15" of water, which is about 0.578psi, it is a very accurate gauge.

- The engine is running at hot idle, as you can see the gauge is registering absolutely nothing which

- means the sump is at atmospheric pressure......

- The vacuum generated by the inlet manifold connection is more than enough to create lots of vacuum in the sump, the problem is that it would need to be carefully controlled, potentially 0.65bar vacuum

- could be created within the sump......but I suspect this would not be a good idea and would suck air past seals, or more of a disaster, suck the front part of the sump gasket into the sump.

- Another problem is that the atmospheric vet on the green filter would need to be partially blocked so that air could not be sucked back at the same rate as it was being pulled out, at the same time this same vent has to allow pressure from the sump which will be generated at high engine loads (piston blowby) to escape unhindered. I am guessing that as a start this hole could be reduced to the same size as the

- aluminium restrictor located in the connection of the cam cover breather to air box.

- Another issue is that the green filter connections just poke through the connection tubes in the

- airbox lid, they are a very sloppy fit. The rubber tubing seals to the airbox lid and not the green filter

- tubes, this means there is lots of leakage within the air box, I would need to make these more air tight.

- So next things to do are improve these joints and reduce the vent exit on the green filter (thanks Dave E. for this idea)

- then re-check for sump vacuum.

Turbo Compressor pressure at idle.

A check I did today was measure the pressure/vacuum at hot idle at the compressor side of the turbo.

This was to see if there was any vacuum influencing oil leakage from the compressor seals.

The easiest and closest take off was the pipe coming from the turbo compressor housing.

- With engine warmed up and running I slowly connected the magnehelic gauge to this outlet, just incase there

- was vacuum and it was more than the gauge could handle.......to my surprise the needle hardly moved at all,

- and when it did, it moved in the opposite direction to that I'd expected !, there was no vacuum at all, in fact

- there was positive pressure, but so small it hardly registered.

- There are 2 ports on the gauge, one for positive and one for negative pressure, so switching the pipe over to

- the positive (high) pressure side.......

Gave this reading..........bugger all..... 0.5" of water = 0.0181 psi

- Given this low reading I increased the rpm to about 2krpm, the reading rose to about 5" of water = 0.181psi, again this

- was positive pressure and not vacuum.