Front

Wheel Camber

- Whenever the suspension struts are disturbed, the wheel

camber and tracking

- should be checked and adjusted where necessary.

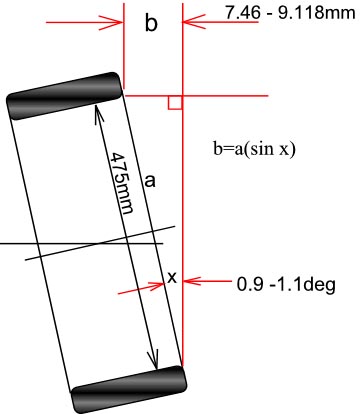

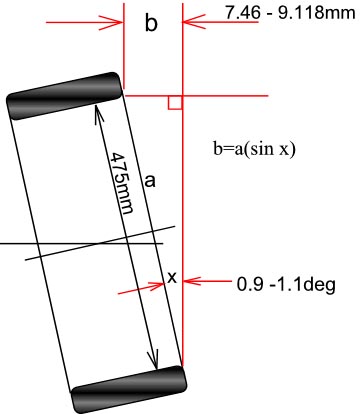

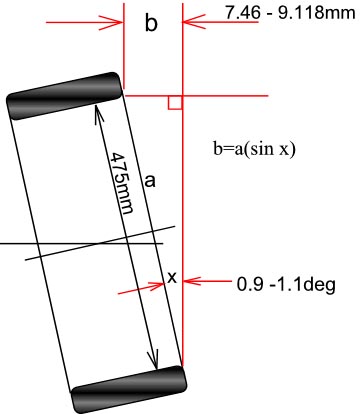

- For camber book figure quotes -0.9 to -1.1deg, which

equates to about 7.5 - 9mm

- gap at the top of wheel rim to plumb spirit level as in

photo below.

- You should be on a flat and level surface and have the

rear suspension at

- normal ride height, also the front seats should be

weighted with 75kg each.

-

- The camber should always be adjusted first because any

movement here will

- also affect the tracking, wheel tracking differences do

not affect camber.

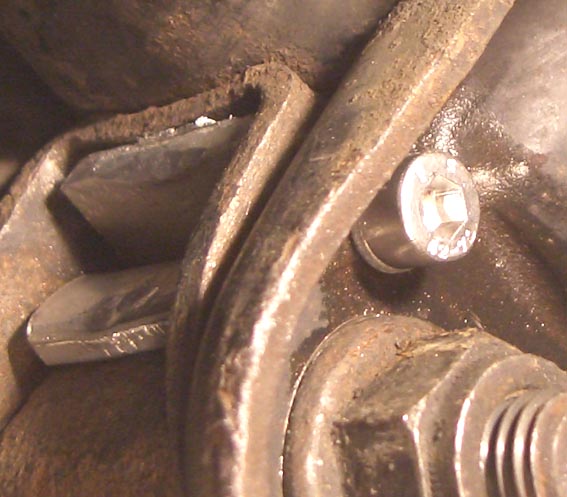

- You can set the camber by loosening the top pinch bolt

(removal not necessary as in pic)

- and bottom bolt and then pulling from the top of the

disc as far as it will go.

- This pulls the axle forging out to its stop in the

slotted upper hole of the strut (ringed)

- and normally this is about right for LC camber. There

seems to be no over adjustment

- because the lower swivel mount plates were extended out

to increase the front wheel base.

-

-

- The reason I removed the bolt completely was to be able

to file the top slotted

- hole in the strut bracket a little longer, about 0.5 -

1.0mm was enough to achieve

- 8mm camber.

-

-

-

- A problem that has been reported by a few owners was

the camber setting slipping

- back which will destroy perfect tyres in no time. To

prevent this I installed a aluminium

- wedge between the axle forging and strut leg body....btw

thanks Ian M for that thought

- couple years ago........

- I would have liked to have them made from a solid

aluminium billet of approx dimensions

- 50mm long, 20mm wide, taper from about 4mm to 5mm (5mm

at the curved end), in the

- event I used 2 bits 3mm thick and seam welded the sides

and formed over at one end so

- it could be removed easily.

-

-

-

- Each side required a slightly differing thickness,

about 0.5mm different overall, and a

- taper of about 0.75-1.00mm, so they were hand filed

until they would just about fit in with

- a few taps of a hammer.

- To secure the wedge in place I drilled and tapped a M5

threaded hole into the side

- of the strut mount plate and a small way into the side

of the wedge. A socket headed

- M5 screw then keeps it from ever falling out.

- Tracking was next, I simply measured the distance

between the inside wheel rims at 3 and

- 9 o'clock positions, here I

am looking for 0.0 - 1.0mm toe in, ie small at front, bigger at rear,

- the movement of the camber had pushed the tracking

about 3-4mm out of alignment.

BACK